The Significance of Aluminum Spreading in High-Quality Manufacturing Techniques

Aluminum casting has become a foundation in high-grade manufacturing strategies. Its light-weight buildings and extraordinary toughness make it a favored option for various sectors. Manufacturers gain from its style adaptability and very little waste generation. As the demand for sophisticated products expands, recognizing the subtleties of aluminum spreading ends up being crucial. This exploration reveals not just its advantages however likewise the progressing innovations that shape its future in manufacturing. What lies in advance for this ingenious process?

The Advantages of Aluminum Casting

Although numerous casting approaches exist, light weight aluminum casting stands out as a result of its various advantages. Among the primary advantages is its light-weight nature, which considerably lowers transport prices and power usage in applications. Light weight aluminum additionally shows exceptional rust resistance, making it excellent for durable parts in diverse atmospheres. The spreading procedure permits for detailed styles, allowing manufacturers to produce intricate shapes with high precision and marginal waste. In addition, aluminum has exceptional thermal and electrical conductivity, making it ideal for a series of commercial applications. The high strength-to-weight ratio enhances the architectural integrity of actors items, supplying resilience without the added mass. Moreover, light weight aluminum casting can be adapted to numerous techniques, such as sand spreading or die casting, which widens its applicability across markets. In general, these benefits setting light weight aluminum casting as a recommended option in contemporary manufacturing, adding to performance and sustainability.

Key Applications of Light Weight Aluminum Casting

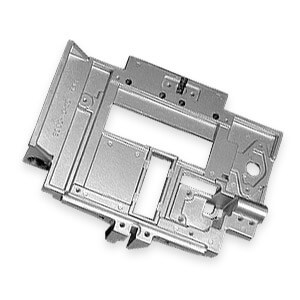

Light weight aluminum spreading locates considerable applications across different sectors due to its useful buildings. In the auto field, it is extensively made use of for manufacturing engine blocks, transmission cases, and wheels, promoting lightweight layouts that boost fuel performance. The aerospace industry likewise profits from aluminum casting, where components such as braces and real estates are generated to meet strict weight and strength requirements.

Furthermore, the electric field utilizes light weight aluminum spreading for producing housings and warmth sinks, which are crucial for efficient thermal administration in digital devices. Aluminum Foundry. The construction market uses light weight aluminum spreadings for architectural elements, home window frameworks, and components, adding to both aesthetics and longevity

The customer products industry integrates aluminum spreading in items like cookware and showing off tools, leveraging the product's strength and deterioration resistance. Generally, the versatility of aluminum spreading makes it an essential procedure in conference diverse production needs throughout numerous fields.

The Refine of Aluminum Spreading

Casting light weight aluminum entails several distinct actions that transform resources right into finished elements. The procedure starts with melting aluminum in a heating system, getting to temperature levels around 660 degrees Celsius. When melted, the fluid aluminum is put into a mold, which takes the form of the preferred part. Various mold and mildew kinds, including sand, irreversible, and financial investment mold and mildews, are utilized relying on the application.

After pouring, the light weight aluminum strengthens and cools down, developing a harsh casting. This casting undertakes a collection of finishing procedures, such as machining, to attain accurate measurements and surface high quality. Quality assurance steps are applied throughout to guarantee the stability and strength of the end product. When all procedures are complete, the finished aluminum parts are all set for numerous applications, showcasing the adaptability and performance of light weight aluminum spreading in production strategies. Each step is crucial in accomplishing high-quality results, making this process vital in producing markets.

Advancements in Aluminum Spreading Modern Technology

Current advancements in aluminum casting technology have transformed production procedures considerably. Developments such as sophisticated casting methods, integration of smart manufacturing, and sustainability techniques are improving the sector. These growths not just improve effectiveness but additionally address ecological worries, leading the way for a much more sustainable future in light weight aluminum spreading.

Advanced Casting Techniques

As producers seek greater efficiency and sustainability in manufacturing, ingenious improvements in aluminum casting modern technology have actually emerged to satisfy these demands. Advanced casting techniques, such as die casting, financial investment spreading, and sand casting, have actually been refined to improve accuracy and decrease waste. Die spreading permits faster manufacturing rates and tighter tolerances, making it ideal for high-volume products. Investment casting, recognized for its capability to produce complicated geometries, allows intricate layouts with remarkable surface coatings. At the same time, sand casting remains preferred for its adaptability and cost-effectiveness, especially in low-volume applications. These approaches not only boost the top quality of aluminum elements yet likewise add to minimized energy usage, lining up with industry goals for lasting practices in producing procedures.

Smart Production Combination

Just how can wise production assimilation change aluminum casting innovation? By including sophisticated modern technologies such as the Web of Points (IoT), expert system (AI), and data analytics, wise production enhances efficiency and precision in light weight aluminum spreading procedures. Real-time monitoring of tools and assembly line enables instant changes, reducing waste and downtime. Predictive maintenance powered by AI lessens tools failings, making sure regular quality. Additionally, data analytics can optimize casting styles and specifications, bring about better product application and decreased cycle times. These advancements promote smooth interaction in between equipments and drivers, cultivating an extra agile production environment. Overall, smart production integration markedly elevates the capabilities of light weight aluminum spreading, promoting higher high quality outcomes and more responsive production methods.

Sustainability Advancements

While the aluminum spreading sector deals with boosting pressure to adopt sustainable techniques, technologies are arising that substantially decrease its ecological impact. Advanced recycling strategies currently enable producers to utilize approximately 95% recycled light weight aluminum, considerably reducing energy intake and waste generation. Additionally, the integration of low-emission technologies, such as electric melting heaters, reduces greenhouse gas emissions related to conventional spreading methods. Furthermore, the growth of green coverings and binders replaces hazardous chemicals, enhancing work environment security and minimizing environmental air pollution. These developments not only align with worldwide sustainability goals but additionally boost the total efficiency and high quality of aluminum items. As the industry evolves, these innovations will certainly play a crucial function in fostering an extra sustainable future for light weight aluminum spreading.

Comparing Aluminum Casting With Various Other Methods

In contrasting aluminum spreading with other producing techniques, several essential elements emerge. Cost stamina, efficiency and toughness, and style flexibility offer as essential metrics for evaluation (Aluminum Casting Company). Analyzing these aspects can provide understandings into the advantages and constraints of light weight aluminum casting in different manufacturing contexts

Expense Efficiency Analysis

Cost effectiveness continues to be an extremely important consideration in producing processes, particularly when examining aluminum casting against different approaches. Aluminum spreading often presents a reduced preliminary investment contrasted to methods such as steel forging or machining, which need more pricey and intricate devices. In addition, light weight aluminum's light-weight nature can lower transportation expenses and power usage throughout production. The ability to develop intricate shapes with very little waste better boosts its cost-effectiveness, as much less product is discarded throughout the manufacturing process. Light weight aluminum casting usually allows for quicker production cycles, leading to reduced labor prices and faster turnaround times. To summarize, when comparing expense performance, light weight aluminum spreading frequently becomes a beneficial option, offering producers financial benefits together with top notch outcome.

Toughness and Durability

Strength and toughness are important elements when evaluating manufacturing methods, especially in the context of aluminum spreading. Compared to other techniques such as plastic shot molding and steel construction, light weight aluminum spreading offers unique benefits. The integral buildings of aluminum, integrated with the spreading process, cause light-weight yet durable parts that can endure considerable stress and ecological factors. Unlike plastics, which may break down with time, light weight aluminum preserves its stability and efficiency under heats and pressures. Furthermore, while steel elements can be larger and vulnerable to deterioration, light weight aluminum withstands rusting, improving durability. This combination of stamina and longevity makes light weight aluminum casting a recommended selection for sectors requiring reputable performance popular applications, such as automobile and aerospace sectors.

Design Adaptability Contrast

The Future of Light Weight Aluminum Casting in Production

How will developments in modern technology shape the future of light weight aluminum casting in production? The combination of automation and expert system is anticipated to transform light weight aluminum casting procedures. These innovations can boost precision and effectiveness, reducing waste and manufacturing costs. Furthermore, the emergence of 3D printing methods permits for fast prototyping and customized layouts, enabling producers to react promptly to market demands.

Sustainability is likewise an essential focus, with innovations focused on decreasing energy intake and reducing environmental effect. Strategies such as die spreading and investment casting are advancing to incorporate recycled aluminum, advertising a round economy.

Additionally, improvements in products scientific research might bring about the advancement of lighter, more powerful light weight aluminum alloys that can increase the applications of light weight aluminum spreading across various industries. Generally, the future of aluminum spreading in manufacturing will likely be characterized by increased versatility, sustainability, and efficiency, placing it as a vital element of modern manufacturing methods.

Regularly Asked Inquiries

Just How Does Aluminum Spreading Influence Environmental Sustainability?

Light weight aluminum casting favorably affects ecological sustainability by advertising recycling, lowering energy intake compared to other steels, and minimizing waste. Its lightweight buildings likewise result in lower discharges during transport, supporting greener practices in different industries.

What Are the Price Ramifications of Aluminum Spreading?

Aluminum spreading typically requires higher preliminary prices as a result of material and handling expenses. Its toughness and lightweight residential properties can yield long-lasting cost savings by reducing maintenance and transport prices, ultimately stabilizing the economic implications for producers.

Can Light Weight Aluminum Spreading Be Recycled Successfully?

Light weight aluminum spreading can be recycled effectively, as the material keeps its buildings throughout the recycling process. This permits the production of top notch parts while reducing waste and decreasing power usage connected with brand-new light weight aluminum manufacturing.

What Safety Steps Are Needed Throughout Light Weight Aluminum Spreading?

Precaution during aluminum casting include utilizing individual safety tools like gloves and safety glasses, guaranteeing appropriate ventilation, preserving equipment, and following protocols for handling molten steel to stop burns, inhalation dangers, and Precision aluminum casting various other prospective accidents.

Exactly How Does Aluminum Casting Affect Product Style Versatility?

Aluminum casting enhances product layout adaptability by making it possible for light-weight frameworks and complex shapes. This strategy permits designers to check out ingenious setups, leading to versatile applications throughout different industries while maintaining toughness and sturdiness in the final products.

Aluminum casting can be adapted to numerous strategies, such as sand casting or die spreading, which expands its applicability throughout markets. When all processes are full, the ended up aluminum components are all set for different applications, showcasing the adaptability and effectiveness of aluminum spreading in manufacturing techniques. As suppliers look for greater performance and sustainability in production, innovative improvements in aluminum spreading innovation have emerged to satisfy these demands. Unlike plastic shot molding, which might require extensive tooling changes for style changes, aluminum spreading can fit modifications much more conveniently during the manufacturing cycle. Developments in products science might lead to the growth of lighter, stronger light weight aluminum alloys that might broaden the applications of aluminum spreading across numerous markets.